Calibration is the cornerstone of reliable pH measurement—ensuring sensor readings align with international standards (ISO 4319:1977, ASTM D1293-19) and regulatory requirements (EPA, FDA 21 CFR Part 11, USP <645>). pH sensors degrade over time due to electrode fouling, membrane aging, chemical exposure, and environmental stress, leading to "drift" (systematic measurement error). The frequency of calibration directly impacts data accuracy, process control efficiency, and compliance—incorrect calibration can result in product defects, regulatory fines, or equipment damage.

This guide provides a technical framework for determining pH sensor calibration frequency, tailored to sensor type, application, and operating conditions. It integrates industry best practices, calibration protocols, and maintenance guidelines to optimize sensor performance and lifespan for laboratory, industrial, and field use.

1. pH Sensor Technology & Calibration Sensitivity

pH sensor design dictates inherent stability and calibration needs—understanding these differences is critical for setting appropriate schedules:

| Sensor Type | Technical Description | Calibration Sensitivity | Typical Stability |

|-------------|-----------------------|-------------------------|-------------------|

| Traditional Glass Electrode Sensors (Two-Electrode) | Glass membrane (Li⁺/Na⁺ doped) + Ag/AgCl reference electrode. Susceptible to fouling, membrane aging, and electrolyte leakage. | High—requires frequent calibration due to drift (±0.02 pH/month). | 6–12 months (industrial use); 1–3 years (laboratory use). |

| Differential pH Sensors (Three-Electrode) | Separate measuring, reference, and ground electrodes. Reduces interference from polarization and fouling. | Moderate—drift minimized (±0.01 pH/month). | 12–24 months (continuous industrial use). |

| Optical pH Sensors (Fluorescence-Based) | No glass membrane; uses pH-sensitive fluorophores. Resistant to fouling, corrosion, and high temperatures. | Low—minimal drift (±0.005 pH/month). | 2–5 years (industrial/commercial use). |

| Single-Use pH Sensors (Disposable) | Pre-calibrated at the factory; intended for single batch or short-term use. | N/A—no user calibration required (valid for 1–30 days post-activation). | Limited to single-use or batch duration. |

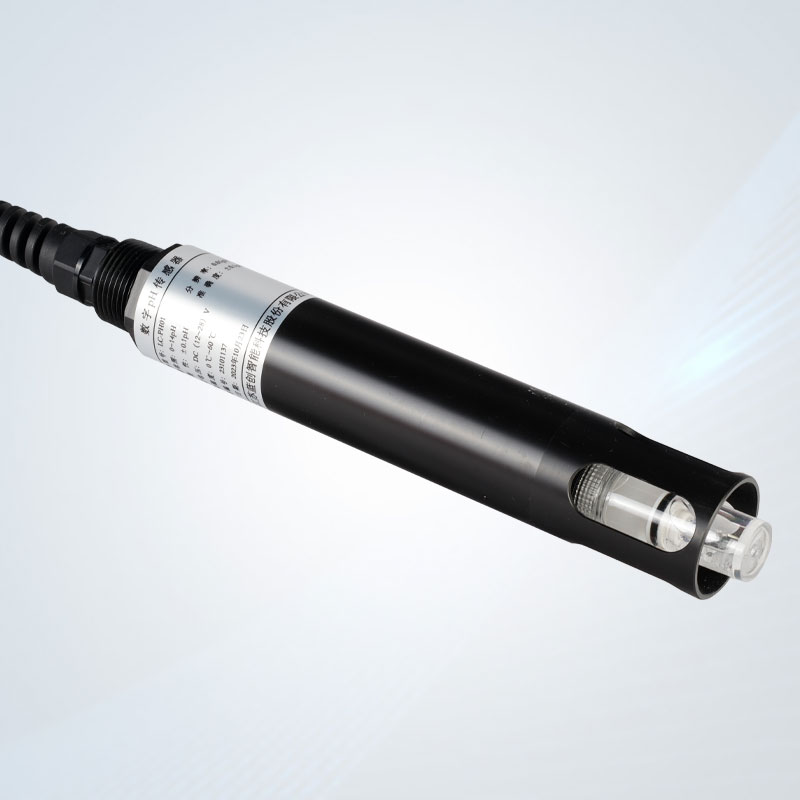

| Online Process pH Sensors (Industrial-Grade) | Ruggedized design (IP67/IP68), self-cleaning mechanisms, and temperature compensation (Pt1000/Pt100). | Moderate—drift dependent on process harshness (±0.01–±0.03 pH/month). | 12–18 months (continuous operation). |

2. Key Factors Determining Calibration Frequency

Calibration frequency is not one-size-fits-all—it is governed by four critical variables:

2.1 Application Precision Requirements

- High-Precision Applications (±0.01 pH tolerance): Pharmaceutical water testing (USP WFI/PW), semiconductor manufacturing (ultra-pure water), and laboratory research. Require frequent calibration to maintain compliance.

- Medium-Precision Applications (±0.05 pH tolerance): Food & beverage production (e.g., wine fermentation, dairy processing), municipal wastewater treatment (effluent pH monitoring).

- Low-Precision Applications (±0.1 pH tolerance): Educational labs, non-critical environmental monitoring (e.g., pond pH), and general process troubleshooting.

2.2 Operating Environment

- Chemical Harshness: Exposure to strong acids (pH <2), bases (pH >12), oxidizers (chlorine, ozone), or organic solvents accelerates membrane degradation and drift—increase calibration frequency by 50%.

- Temperature Extremes: Operating outside 10–40°C amplifies drift (pH shifts ~0.03 pH/°C without compensation). Sensors in high-temperature processes (e.g., chemical reactors, 80–100°C) require weekly calibration.

- Fouling Potential: Solutions with high turbidity, suspended solids, proteins, or oils (e.g., wastewater, food processing) cause membrane fouling—calibrate after every 5–10 uses or weekly for continuous operation.

- Pressure: High-pressure applications (>10 bar) can affect reference electrode junction integrity—calibrate biweekly.

2.3 Usage Intensity

- Continuous Operation (24/7): Online sensors in water treatment, chemical processing, or bioreactors degrade faster—calibrate more frequently than intermittent-use sensors.

- Intermittent Use: Laboratory bench meters or field sensors used 1–2x/week have lower drift—calibrate before each use or monthly.

2.4 Regulatory Compliance

- GMP/GLP Environments: Pharmaceutical, biotech, and food industries require documented calibration (per FDA 21 CFR Part 11) with predefined frequencies (e.g., daily for critical processes).

- Environmental Monitoring: EPA mandates calibration before each sampling event or at least quarterly for continuous monitors (Method 150.1).

3. Calibration Frequency Guidelines by Application

Below are industry-proven calibration schedules, aligned with precision requirements and operating conditions:

| Application Category | Calibration Frequency | Rationale |

|----------------------|-----------------------|-----------|

| Laboratory High-Precision (e.g., USP WFI testing, analytical chemistry) | Before each use + daily verification with a secondary buffer. | Ensures ±0.01 pH accuracy for regulatory compliance and research reproducibility. |

| Industrial Continuous Process (e.g., chemical reactors, RO water treatment) | Weekly (standard conditions) or biweekly (harsh environments: pH <2, pH >12, high fouling). | Maintains ±0.05 pH control for process efficiency and product consistency. |

| Municipal Wastewater Treatment (influent/effluent monitoring) | Weekly calibration + monthly verification with NIST-traceable standards. | Complies with EPA discharge limits (pH 6.5–8.5) and accounts for high fouling. |

| Food & Beverage Production (e.g., wine fermentation, dairy pH control) | Before each batch + daily calibration for continuous lines. | Prevents microbial growth (pH <4.6 for canned foods) and ensures product quality. |

| Field Environmental Monitoring (e.g., river/lake sampling) | Before each sampling event + calibration check after 10 samples. | Mitigates drift from temperature and transport stress. |

| Educational/Non-Critical Use (e.g., classroom labs, pond monitoring) | Monthly or before each use (if stored >2 weeks). | Balances accuracy and practicality for low-stakes applications. |

| Single-Use Sensors | No user calibration (factory-calibrated; discard after use or expiration). | Pre-calibrated for 1–30 days—validity specified by manufacturer. |

4. Professional Calibration Process & Best Practices

Calibration frequency is only effective if paired with proper technique—follow these steps to ensure accuracy:

4.1 Pre-Calibration Preparation

- Select Buffers: Use NIST-traceable buffer solutions (e.g., 4.01, 7.00, 10.01 pH at 25°C) that cover the sensor’s operating range. Avoid expired buffers (shelf life: 6–12 months for sealed containers).

- Condition the Sensor: Hydrate glass membrane sensors in 3 M KCl solution for 30 minutes before calibration (prevents dry-membrane drift).

- Clean the Sensor: Remove fouling with:

- Protein-based fouling: 1% pepsin/HCl solution (soak 10 minutes).

- Mineral scale: 0.1 M HCl (soak 5 minutes) or 0.1 M EDTA (for hard water deposits).

- Organic fouling: Isopropyl alcohol (wipe gently with a lint-free cloth).

Rinse thoroughly with deionized water (DIW) after cleaning.

4.2 Calibration Technique

- Two-Point vs. Three-Point Calibration:

- Two-point: For narrow pH ranges (e.g., 4–7 pH) or medium precision—use buffers bracketing the sample pH.

- Three-point: For wide ranges (e.g., 2–12 pH) or high precision—includes acidic, neutral, and alkaline buffers.

- Temperature Compensation: Ensure buffers and samples are at the same temperature (or use a sensor with built-in Pt1000 RTD for real-time compensation).

- Calibration Sequence: Immerse the sensor in the neutral buffer (7.00 pH) first, then acidic (4.01 pH) or alkaline (10.01 pH)—allow 1–5 seconds for stabilization (T90 response time).

- Adjustment: Follow the manufacturer’s instructions to align the sensor reading with the buffer pH (modern meters auto-calibrate; manual meters require potentiometer adjustment).

4.3 Post-Calibration Verification

- Test the sensor in a verification buffer (not used for calibration) to confirm accuracy. Acceptable tolerance: ±0.02 pH for high-precision applications; ±0.05 pH for industrial use.

- If readings are outside tolerance, repeat calibration with fresh buffers or clean the sensor again.

4.4 Data Integrity & Documentation

- Record calibration details per regulatory requirements (21 CFR Part 11, ISO 9001):

- Buffer lot number, expiration date, and temperature.

- Sensor ID, calibration date/time, and operator.

- Before/after calibration readings and adjustments.

- Verification results.

- Store calibration records electronically (encrypted) or in a secure, audit-ready format.

5. Maintenance to Extend Calibration Intervals

Proactive maintenance reduces drift and extends the time between calibrations:

- Storage:

- Glass electrode sensors: Store in 3 M KCl solution (never DIW, which dries the membrane).

- Optical sensors: Store in manufacturer-recommended storage solution or dry (per instructions).

- Long-term storage (>1 month): Remove the sensor from the meter and seal the membrane to prevent electrolyte leakage.

- Regular Cleaning: Clean after each use with DIW; perform deep cleaning monthly for continuous-use sensors.

- Electrode Replacement: Replace glass electrodes every 6–12 months (industrial) or 1–3 years (laboratory); replace reference electrolytes if leakage is detected (crystallization around the junction).

- Avoid Contamination: Use dedicated buffers for calibration (never reuse buffer solutions after sensor immersion).

6. Troubleshooting: When to Calibrate More Frequently

If you observe any of the following, increase calibration frequency or perform an unscheduled calibration:

- Drift: Readings shift by >0.05 pH over 24 hours (continuous use) or >0.1 pH between uses.

- Slow Response: Sensor takes >10 seconds to stabilize (indicates fouling or membrane degradation).

- Inconsistent Readings: Duplicate measurements vary by >0.03 pH.

- Out-of-Spec Samples: Process or sample pH is outside expected ranges (e.g., wastewater effluent pH >8.5 despite chemical dosing).

7. Technological Advancements: Smart Calibration Solutions

Modern pH sensors integrate features to simplify calibration and reduce frequency:

- Auto-Calibration: Industrial online sensors (e.g., Endress+Hauser Liquiline CM442) automatically calibrate using built-in buffer reservoirs—reducing human error and maintenance.

- Diagnostic Alerts: Smart sensors (e.g., Hach HQd) provide drift warnings, fouling alerts, and calibration reminders via IoT platforms.

- Predictive Maintenance: AI-powered sensors (e.g., Thermo Fisher Orion Star A211) analyze usage data to recommend calibration intervals based on actual operating conditions.