Comprehensive solution for dust explosion prevention monitoring, warning and control

Overview of the plan

The plan is based on the construction concept of "automated early warning, hierarchical closed-loop, and strengthening enterprise and grassroots responsibilities". Through AI intelligent analysis models, the real-time monitoring of equipment operation status is achieved. With the establishment of a risk feature library and effective database, risks such as abnormal equipment operation, equipment failure, and failure of safety protection measures are effectively identified. When abnormalities occur, they will be pushed in the first time to urge enterprises to timely handle and eliminate the factors affecting the rise of risks, resolutely prevent risks from evolving into hidden dangers and turning into accidents, and assist enterprises in implementing their main responsibility for safety production.

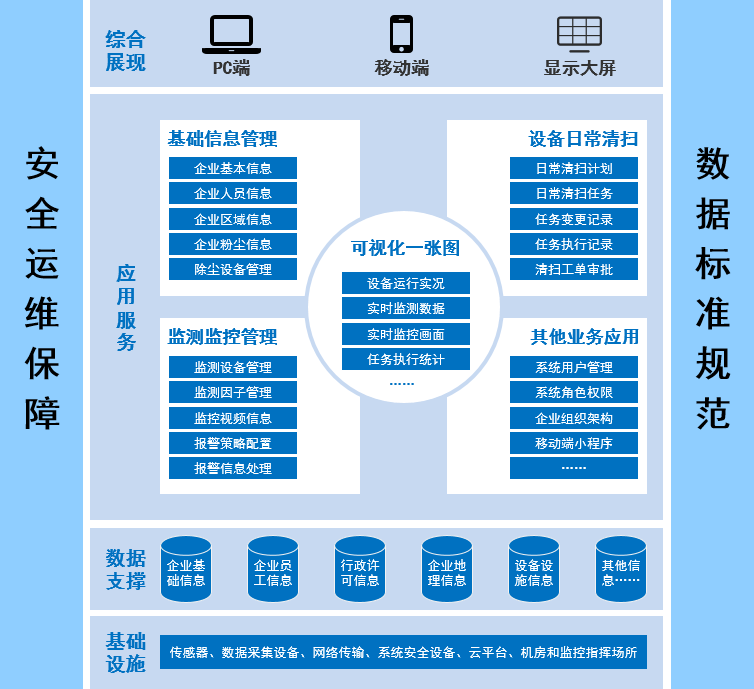

Scheme composition

1. Basic information management: Integrate management of enterprise, personnel, region, dust and other information, convert paper documents into electronic files, so that production and management personnel of the enterprise can participate in the supervision of dust explosion prevention, and timely discover risk situations involved in the production process of the enterprise.

2. Monitoring and early warning management: Real time monitoring of the operation status of the dust removal system, establishing a systematic, comprehensive, and real-time comprehensive monitoring and management system, conducting early warning, forecasting, and analysis of various factors and behaviors related to powder explosions, summarizing events, and providing initial response strategies and plans.

3. Equipment cleaning management: In order to prevent dust from reaching explosive concentrations, a closed-loop process of "initiating plans - issuing tasks - executing tasks - reviewing execution status - recording and archiving" is implemented to urge enterprises to clean the site in a timely manner, reduce dust accumulation on site, and lower the hazards of explosions and secondary explosions.

4. Visual display: Connect the basic data, dynamic perception data, and real-time video monitoring images of dust explosion related enterprises. Through data aggregation and analysis, form a safety production risk assessment system and graded warning "one map" for dust explosion related enterprises.

Program features

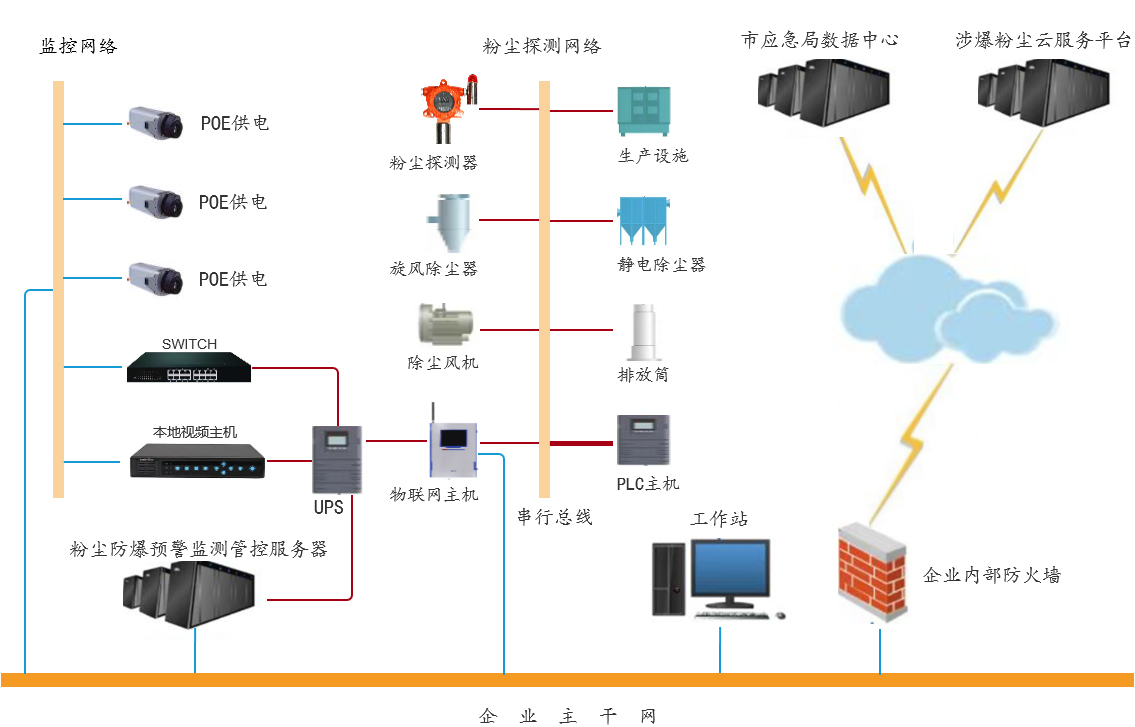

1. Intelligent change, digital transfer, joint prevention and control supervision: with the construction concept of "5G Internet plus+intelligent online monitoring system", the perception data of the enterprise's internal dedusting system and the monitoring video of key parts, basic data, perception data of the dedusting system, video data, key safety parameters of the deduster and other information are gathered together to achieve full time unattended supervision of the operation site and dedusting equipment.

2. 'Civil defense+technical defense', graded warning and control: Regular self inspection of hidden dangers can be carried out for important places and key parts, and coordinated according to the three-level alarm mechanism, the system can accurately predict, advance warning and graded response functions, achieve more timely alarm, faster response and more effective disposal, consolidate employees' awareness of safety production responsibility, and improve the management level of safety risk control ability.

3. High standard and standardized platform construction: Strictly implement the highest standards of various industries, ensure that the entire platform follows the information system and relevant industry standards, closely monitor and respond to the data docking requirements of customers and higher-level emergency, environmental protection and other departments, and ensure that the platform can operate smoothly and seamlessly with the requirements of superiors after construction.

Application scenarios