In industrial process control, water treatment, environmental monitoring, and laboratory analysis, ORP (Oxidation-Reduction Potential) and pH sensors are foundational analytical tools for quantifying aqueous solution properties. While both rely on electrochemical principles to generate measurable signals, they target distinct chemical phenomena: pH quantifies hydrogen ion activity (acidity/alkalinity), while ORP characterizes electron transfer potential (oxidative/reductive capacity). Understanding their technical differences—rooted in chemistry, design, and application—is critical for ensuring regulatory compliance (e.g., EPA, FDA, ISO) and optimizing process efficiency.

This article systematically contrasts ORP and pH sensors across key technical dimensions, including chemical principles, hardware design, calibration protocols, industry applications, and limitations—providing a technical framework for process engineers, laboratory technicians, and facility managers.

1. Core Definitions & Chemical Principles

1.1 pH Sensors

- Definition: pH (potential of hydrogen) measures the activity of hydrogen ions (H⁺) in a solution, defined by the Nernst equation and standardized per ISO 4319:1977. It quantifies acidity (H⁺ > OH⁻) or alkalinity (OH⁻ > H⁺) on a logarithmic scale (0–14), with 7.0 as neutral (25°C).

- Chemical Principle: pH sensors operate via the Nernst equation, which relates the electrode potential (E) to hydrogen ion activity ([H⁺]):

\[

E = E^0 + \frac{2.303RT}{nF} \log_{10}[H^+]

\]

Where:

- \( E^0 \) = standard electrode potential (0.241 V for Ag/AgCl reference),

- \( R \) = gas constant, \( T \) = temperature (K), \( n \) = number of electrons (1 for H⁺), \( F \) = Faraday constant.

At 25°C, the equation simplifies to \( E = 0.241 - 0.0591 \times pH \), meaning a 1 pH unit change corresponds to a 59.1 mV potential shift.

1.2 ORP Sensors

- Definition: ORP (also called redox potential) measures the electrochemical potential difference between a solution and a standard reference electrode (Standard Hydrogen Electrode, SHE), per ASTM D1498-14. It quantifies the solution’s tendency to accept (oxidizing, positive mV) or donate (reducing, negative mV) electrons.

- Chemical Principle: ORP sensors detect the net redox potential of all oxidizable/reducible species (e.g., Cl₂, Fe²⁺, sulfide) in a solution. The measured potential (vs. SHE) reflects the equilibrium between oxidized (Ox) and reduced (Red) forms:

\[

E_{ORP} = E^0 + \frac{2.303RT}{nF} \log_{10}\left(\frac{[Ox]}{[Red]}\right)

\]

Unlike pH, ORP has no absolute "neutral" point—values are relative to SHE (0 mV), with typical ranges: -1000 mV (strongly reducing, e.g., anaerobic wastewater) to +1200 mV (strongly oxidizing, e.g., chlorinated water).

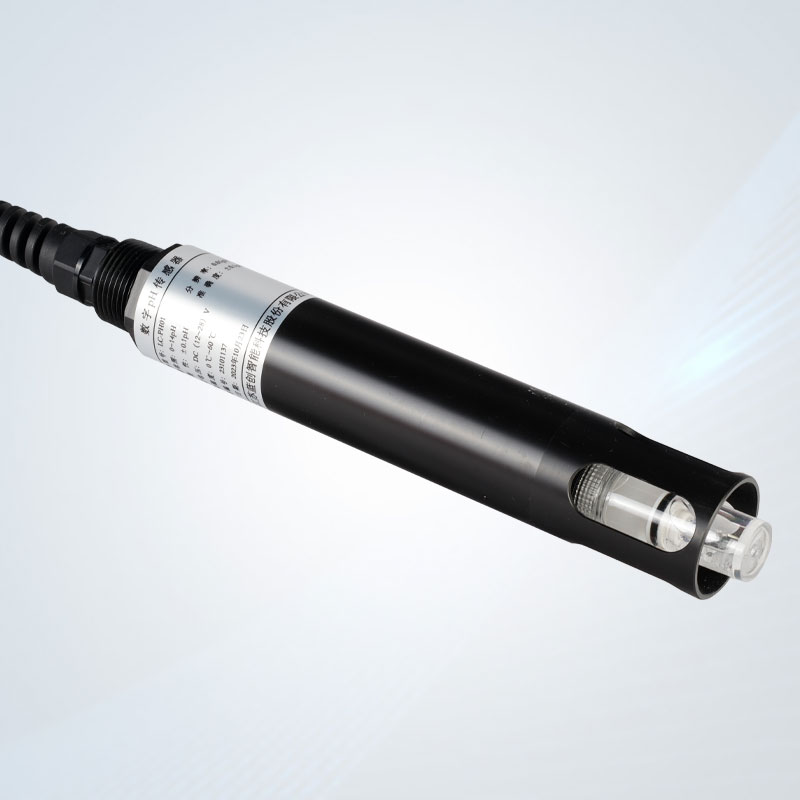

2. Sensor Design & Hardware Differences

| Component | pH Sensor | ORP Sensor |

|-----------|-----------|------------|

| Measuring Electrode | Glass membrane (silicate-based) doped with Li⁺ or Na⁺ ions—selective for H⁺. | Inert metal (platinum, gold, or palladium)—catalyzes redox reactions without participating. |

| Reference Electrode | Ag/AgCl (silver-silver chloride) with KCl electrolyte (3 M or saturated) and porous junction (ceramic or PTFE) for ion exchange. | Same Ag/AgCl reference as pH sensors (or SHE for laboratory use). |

| Temperature Compensation | Mandatory (Pt1000/Pt100 RTD)—pH shifts ~0.03 pH units per °C (e.g., 25°C → 35°C = +0.3 pH error without compensation). | Critical for accuracy—ORP changes ~1–2 mV per °C (varies by solution). |

| Housing Material | Chemically resistant polymers (PVDF, PPS) or glass—compatible with most solutions except hydrofluoric acid (HF). | Inert metals or polymers—resistant to corrosive oxidizers (e.g., chlorine) and reducers (e.g., sulfide). |

3. Key Technical Differences (Tabulated)

| Parameter | pH Sensor | ORP Sensor |

|-----------|-----------|------------|

| Primary Measurement | Hydrogen ion activity ([H⁺]) → acidity/alkalinity. | Net electron transfer potential → oxidative/reductive capacity. |

| Units | pH (dimensionless, 0–14). | Millivolts (mV, relative to SHE: -1000 to +1200 mV). |

| Calibration Standards | NIST-traceable buffer solutions (e.g., 4.01, 7.00, 10.01 pH at 25°C). | Quinhydrone standard solutions (e.g., 100 mV, 400 mV) or Zobell’s solution (660 mV at 25°C). |

| Typical Operating Range | 0–14 pH (industrial); 2–12 pH (practical, to avoid glass membrane damage). | -500 to +1000 mV (industrial); -1000 to +1200 mV (laboratory). |

| Electrode Selectivity | Highly selective for H⁺ (glass membrane excludes most ions). | Non-selective—responds to all redox-active species (e.g., Cl₂, Fe²⁺, NO₃⁻, sulfide). |

| Critical Interferences | - HF (etches glass membrane).<br>- High ionic strength (alters activity coefficients).<br>- Protein/fouling (blocks membrane pores). | - Heavy metals (poison Pt electrode).<br>- Organic fouling (reduces electron transfer).<br>- Dissolved oxygen (affects redox equilibrium). |

| Response Time (T90) | 1–5 seconds (laboratory); 5–10 seconds (industrial, fouling-prone). | 2–10 seconds (depends on solution mixing and electrode cleanliness). |

4. Industry Applications & Regulatory Context

pH is a critical control parameter for processes where acidity/alkalinity directly impacts product quality, safety, or equipment longevity:

- Water Treatment: Maintain pH 6.5–8.5 (EPA Clean Water Act) to optimize coagulation, disinfection, and corrosion control in distribution systems.

- Food & Beverage: Control pH <4.6 (FDA 21 CFR Part 113) to inhibit Clostridium botulinum growth in canned foods; adjust pH 3.2–3.6 in wine fermentation (regulates yeast activity).

- Pharmaceuticals: Ensure purified water (PW) pH 5.0–7.0 (USP <645>) and water for injection (WFI) pH 5.0–7.0 (EP 2.2.38) to prevent product degradation.

- Chemical Manufacturing: Control pH in neutralization reactions (e.g., acid waste treatment to pH 6–9) to meet discharge regulations and protect equipment.

4.2 ORP Sensor Applications

ORP is used to monitor redox reactions, disinfection efficacy, and chemical stability—where electron transfer drives process outcomes:

- Water Disinfection: Verify chlorine (650–750 mV), ozone (700–800 mV), or peroxide (400–500 mV) efficacy in drinking water (EPA Method 330.5).

- Swimming Pools: Maintain ORP 650–750 mV (ANSI/APSP-11) and pH 7.2–7.8 (maximizes chlorine disinfection efficiency—pH >8.0 reduces Cl₂ effectiveness by 50%).

- Wastewater Treatment: Monitor ORP in anaerobic digesters (-200 to -400 mV) to optimize methane production; track aerobic treatment (+200 to +400 mV) for BOD reduction.

- Electroplating: Control ORP in plating baths (e.g., +300 to +500 mV for nickel plating) to ensure uniform metal deposition.

5. Calibration & Maintenance Best Practices

5.1 pH Sensor Calibration & Maintenance

- Calibration: Use 2–3 point calibration with NIST-traceable buffers (cover the operating pH range). Perform daily for high-precision applications (e.g., pharmaceuticals) or weekly for industrial use.

- Storage: Immerse the glass electrode in 3 M KCl solution (never deionized water) to prevent membrane drying; store at 2–8°C for long-term stability.

- Cleaning: Remove protein fouling with 1% pepsin/HCl solution; dissolve mineral scale with 0.1 M HCl; avoid abrasive cleaners (scratch glass membrane).

5.2 ORP Sensor Calibration & Maintenance

- Calibration: Use a single-point calibration with a quinhydrone standard (matches expected ORP range). Verify with a secondary standard (e.g., Zobell’s solution) quarterly.

- Storage: Keep the platinum electrode in deionized water or the process solution (avoids oxidation of the metal surface).

- Cleaning: Remove organic fouling with isopropyl alcohol; polish platinum surface with alumina powder (0.3 μm) to restore electron transfer—avoid harsh chemicals (e.g., ammonia) that poison the electrode.

6. Synergistic Use of ORP and pH Sensors

In many industrial processes, pH and ORP are interdependent—monitoring both provides a comprehensive view of solution chemistry:

- Chlorine Disinfection: pH directly affects ORP: at pH 7.0, 97% of Cl₂ is in the active HOCl form (ORP ~700 mV); at pH 8.0, only 30% is HOCl (ORP drops to ~650 mV). Adjusting pH optimizes ORP and disinfection efficiency.

- Reverse Osmosis (RO) Systems: pH 6.0–8.0 (prevents membrane degradation) and ORP <200 mV (avoids oxidative damage to polyamide membranes) are critical for long-term RO performance.

- Aquaculture: Maintain pH 7.0–8.5 (supports fish respiratory function) and ORP 200–400 mV (indicates adequate dissolved oxygen and low toxic sulfide levels).

7. Technical Advancements & Future Trends

Modern ORP and pH sensors integrate Industry 4.0 capabilities to enhance usability and data integrity:

- IoT Integration: Wireless sensors (LoRaWAN, Wi-Fi) transmit real-time data to cloud platforms (e.g., AWS IoT, Siemens MindSphere) for remote monitoring and predictive maintenance.

- Smart Calibration: Algorithms auto-adjust for temperature, drift, and buffer stability—reducing human error and calibration time.

- In-Situ Self-Cleaning: Ultrasonic or wiper-based systems remove fouling in harsh environments (e.g., wastewater, food processing), extending electrode lifespan by 50%.

- Digital Signal Processing: OPC UA connectivity enables seamless integration with DCS/SCADA systems, supporting closed-loop process control (e.g., automatic acid/base dosing based on pH/ORP feedback).