Overview of the plan

This plan is based on GIS+3D oblique photography to construct a virtual reality scene for enterprises, with the goal of effectively preventing and resolving major safety risks. It highlights the advantages of functional and form compliance, secondary safety standardization, and dual prevention operation effectiveness analysis. It strengthens the functions of safety information archives, hazard monitoring and early warning, risk grading control, inspection and hidden danger closed-loop disposal, special operation electronicization, and real-time personnel positioning. It empowers chemical enterprises in perception, monitoring, early warning, disposal, and evaluation, realizes the digital transformation and intelligent upgrading of enterprise safety risk control, helps government departments to do a good job in supervision and management, effectively implements the main responsibility of enterprise safety production, and provides decision-making basis for regulatory departments' law enforcement.

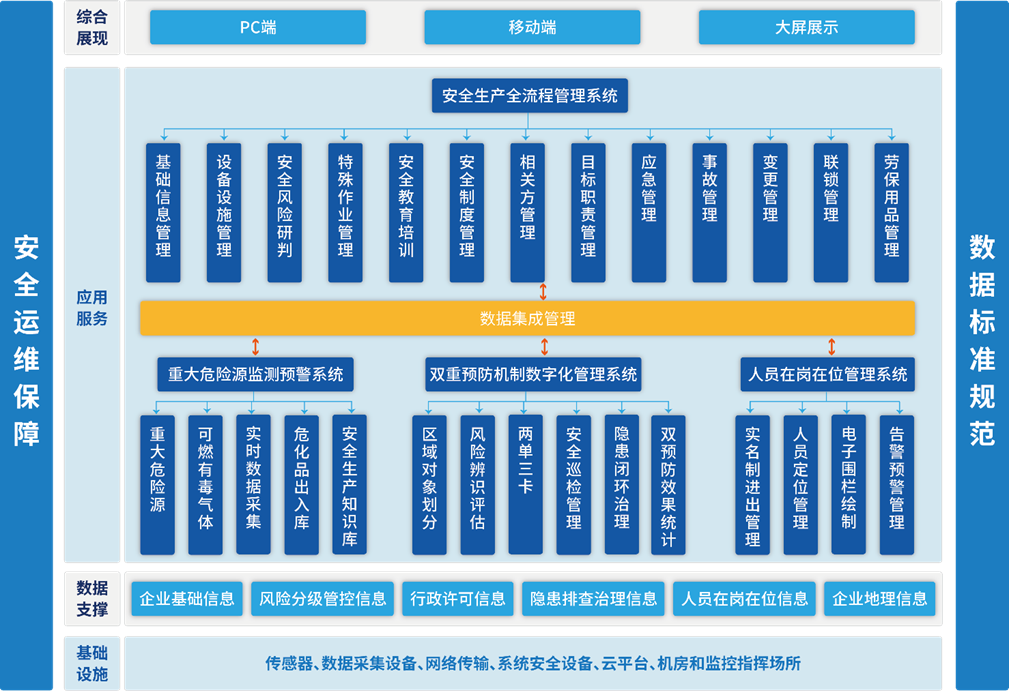

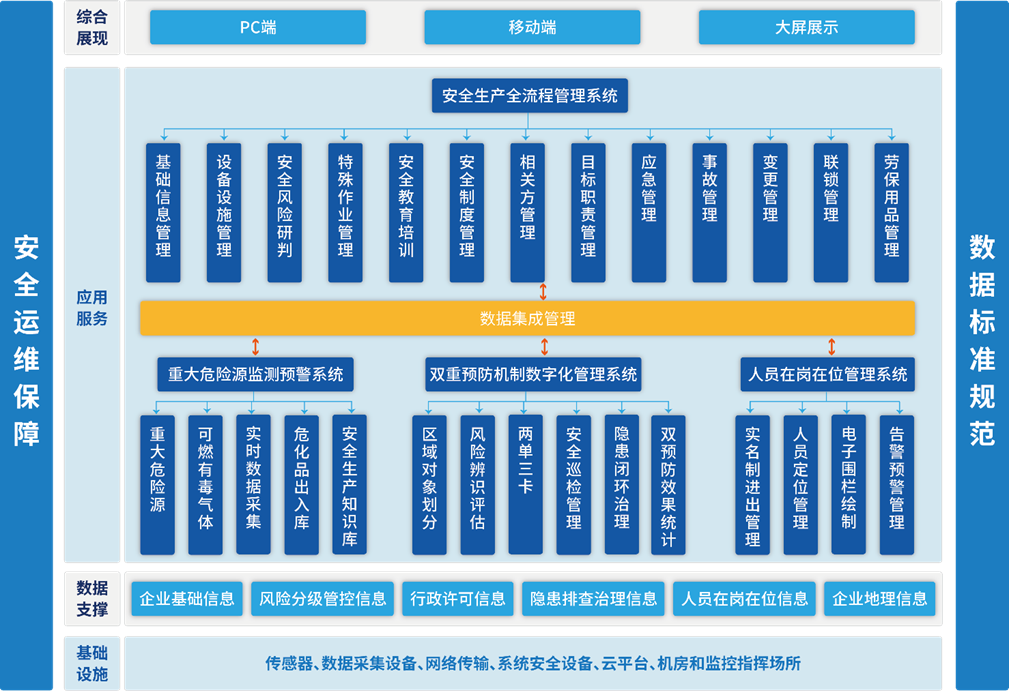

Scheme composition

1. Major hazard monitoring and early warning system: used to monitor real-time data and warnings of hazardous chemical storage and production equipment that constitute major hazard sources in chemical enterprises, as well as monitoring and warning of combustible and toxic gases and safety parameters of hazardous chemical processes, monitoring videos, and other information.

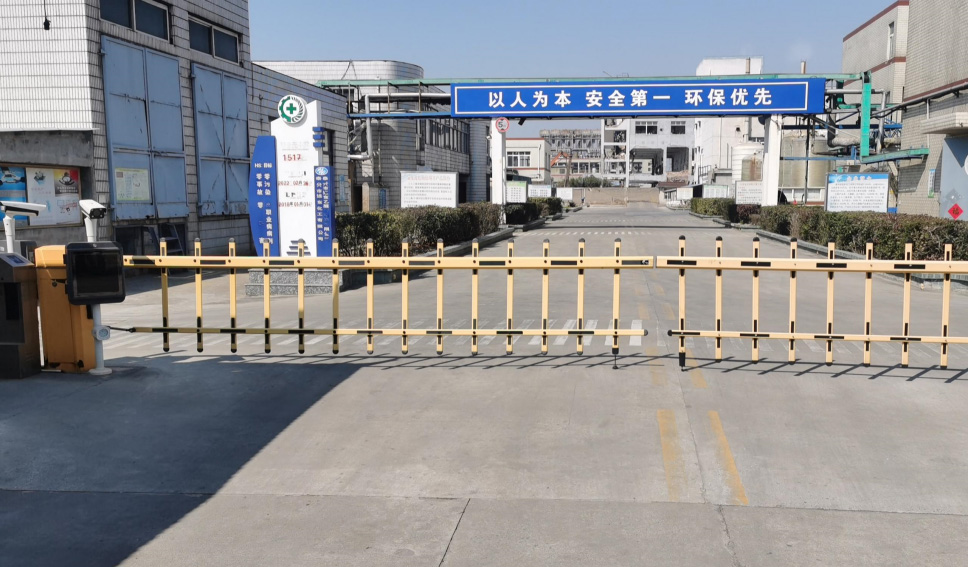

2. Personnel on duty management system: used to manage the scheduled, personnel, and job performance of chemical enterprise operators. It can effectively identify and track the location and behavior of operators and vehicles through technologies such as biometric recognition, intelligent access control, and real-time positioning.

3. Safety Production Full Process Management System: Integrating chemical enterprise safety production standardization and process safety management elements, helping enterprises effectively manage risks, optimize enterprise safety management systems, and improve management efficiency.

4. Dual prevention mechanism digital management system: Based on the fully closed-loop theoretical foundation of "identifying risks, controlling risks, and addressing hidden dangers", it helps enterprises complete the construction of a dual prevention mechanism of risk grading control and hidden danger investigation and governance. By strengthening daily risk control and hidden danger governance of enterprises, it achieves comprehensive safety control of chemical enterprises and helps enterprises achieve the "five haves" requirements.

Program features

1. Comprehensive perception: Real time monitoring is conducted through the positioning, identity, license plate, compliance data of the enterprise's safety production environment, as well as concentration, temperature, pressure, and interlocking switching signals during the production process, to establish a systematic, open, and multi-source comprehensive monitoring and management system.

2. Full participation: Through information technology, all production and management personnel of the enterprise can participate in the safety production of the enterprise, timely discover the risk situations involved in the production process of the enterprise, and effectively enhance the safety production management capability of the enterprise by combining the two single three card and four-color zoning of the safety zone, empowering the safety production of the enterprise.

3. Warning analysis: Establish an intelligent model analysis library and emergency management case library to conduct warning and forecasting analysis on various safety production factors and behaviors, summarize events, and provide initial response strategies and plans.

4. Intelligent integration: Through a secure system architecture, it supports integration with DCS online monitoring, factory online monitoring, video surveillance management information systems, etc., forming a management center for enterprises and comprehensively enhancing their information management capabilities.

Application cases

1. Construction project of enterprise safety production informatization platform for Taixing Fine Chemical Co., Ltd

2. Construction project of enterprise safety production informatization platform for Jiangsu New Material Technology Co., Ltd

3. Construction project of enterprise safety production information platform for a Chemical Co., Ltd. in Jiangsu Province

4. Construction project of enterprise safety production information platform for a Chemical Co., Ltd. in Taixing